ATOTECH INDIA LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ATOTECH INDIA LTD.

Plating On Plastics

Features and benefits

Comprehensive solutions for plating on plastics

Adhemax® for conventional plating ABS, PP and ABS/PC blends with outstanding selective plating properties

Reduced number of process and rinsing steps for direct plating ABS and ABS/PC blends with NeoLink®

Adhemax® PA for plating on polyamide (PA)

Hard Chrome Electrolytes

HEEFhard chrome systems

Worldwide leading proprietary hard chrome process based on the use of high purity, patented additives

Properties of the deposited coatings are continuously matched to current industrial requirements

Highly economical due to improved current efficiency

Excellent wear resistance and high level corrosion protection

Increase in component lifetime

Pb And Cd Free Electroless Nickel Processes

ELV, WEEE and RoHS compliant

Nichem® 11 product range allows electroless nickel plated parts to be recycled safely

Pb and Cd-free deposits for all applications within the automotive, electrical and electronics industries

Comparable or even better performance next to traditionally stabilized electroless nickel processes

Paint Pretreatment

UniPrep® – long life, low temperature cleaners

Low temperature operation

Extended cleaner life

Maintains stable performance throughout cleaner life

Interlox® – phosphorus-free paint adhesion promoters

Superior process stability

Multi-metal application capabilities

Low temperature operation

Minimal sludge and scale formation

Phosphorus-free

Contributing To A Sustainable Production

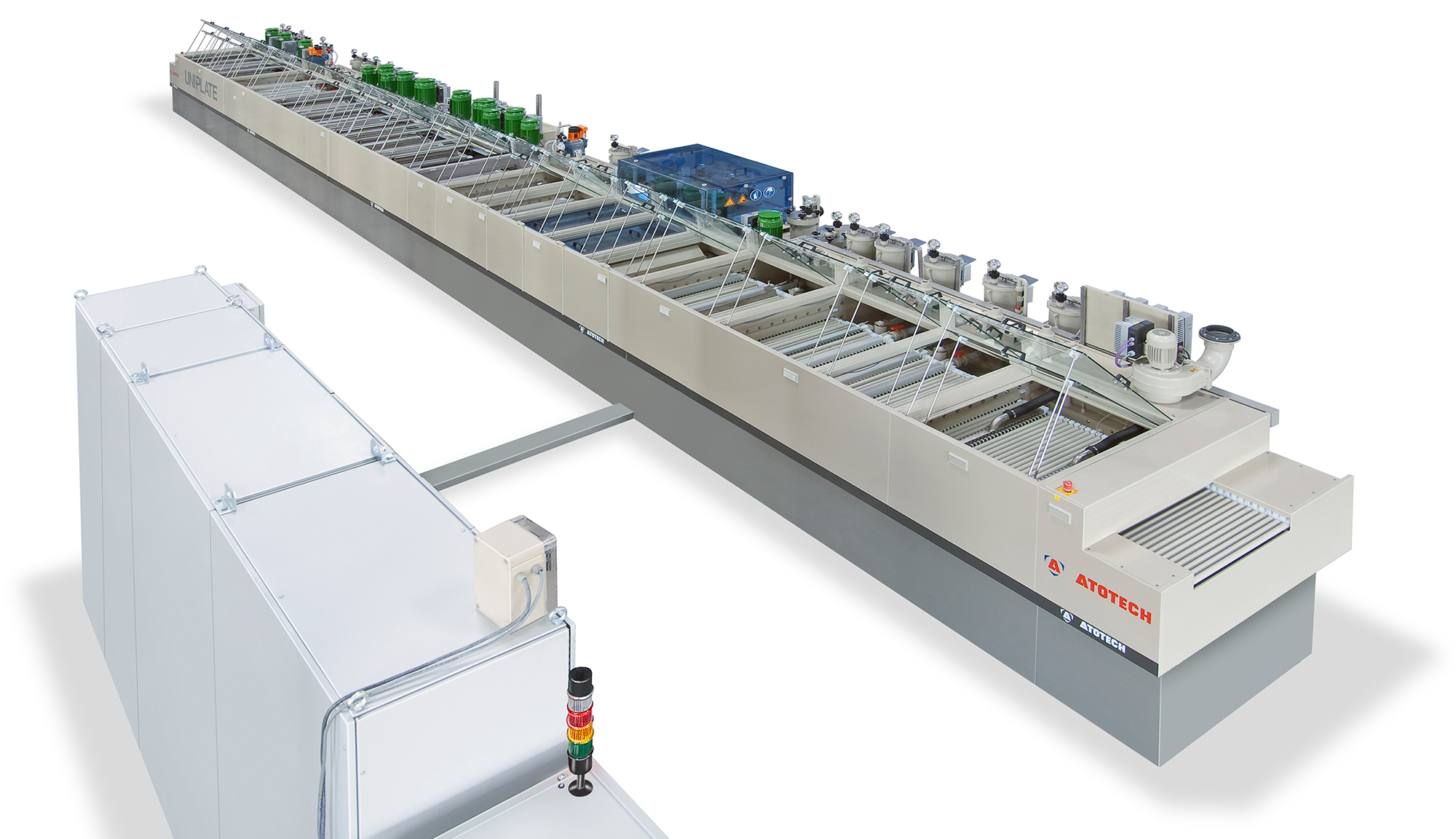

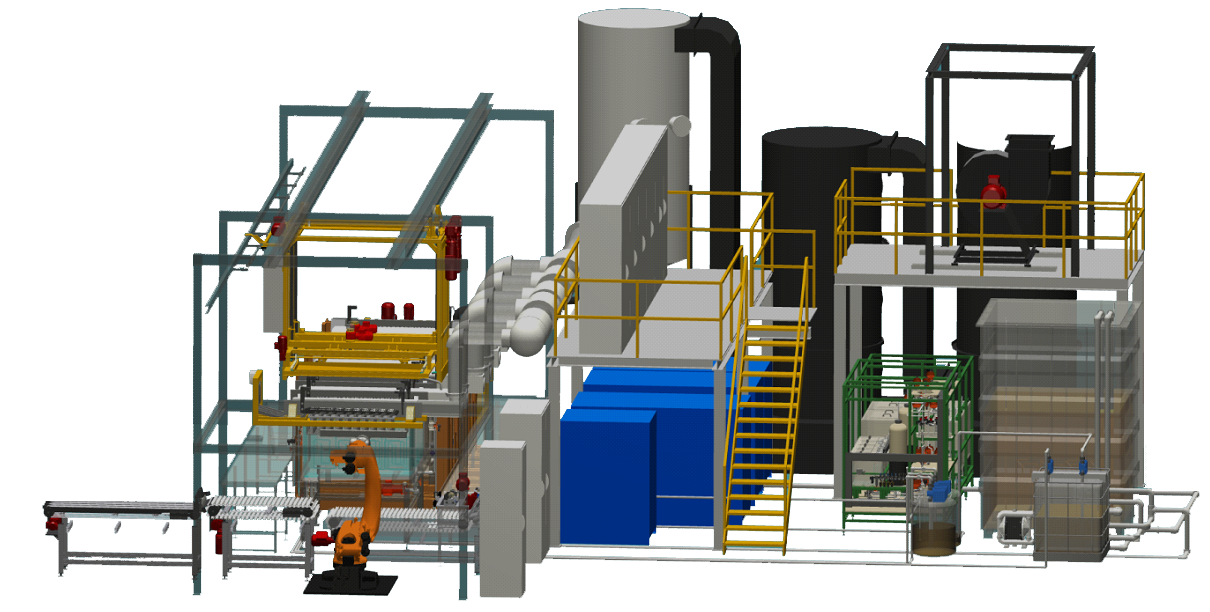

For 60 years Atotech has designed and produced systems for the plating industry at the Atotech site in Feucht close to Nuremberg (Germany) and since 2003 also in Guangzhou (China). Chemical and equipment engineers work closely together to assure the compatibility of chemical processes and lines. Atotech’s equipment technology contributes to minimize energy consumption e.g. with optimized exhaust air system and wastewater reduction, efficient pumps and motors, in combination with control system intelligence.

A team of Atotech equipment and process specialists audits existing plating systems and develops proposals to optimize throughput, automation and quality. Based on the diverse production requirements and conditions, our experts set up tailor-made consulting packages including training, a hotline, service and

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.